Solution Description

Water ring vacuum pump

| Water ring vacuum pump | |

| Product | 2BE1 |

| DN(flange) | eighty~800mm |

| Ability | a hundred and fifty~27000m³/h, with 2950RPM, 1450RPM, 980RPM, 740RPM, 585RPM, 490RPM, 372RPM, 298RPM |

| Head | five~180m |

| Permitting working pressure | two.5Mpa |

| Medium Temperature | Regular<=80°C, cooling structure<105°C, equal to or higher than 105°C take special orders |

| Substance | Cast iron-HT200, HT250 SS304, SS316, SS316L, Duplex SS |

| Partical | 80mg/l |

| Motor | 380V, 415V, 660V IP54, IP55 50Hz, 60Hz |

| Shaft | Cast steel, 2Cr13 |

| Casing and cover | Cast iron, Nudular cast iron, Cast steel |

| Impeller | Cast iron, Bronze, stainless steel |

| Mouth seal | Cast iron, nudular cast iron, bronze, stianless steel. |

| Shaft seal | Mechanical seal or packing seal |

| Bearing | Closed grease lubricated roller bearing(SKF, NTN) NSK thrust and roll bearing |

| Flange standard | ASME, DIN, GB |

| Seal by | Burgmann mechanical seal or gland packing |

| Quality control system | ISO9001:2000, ISO14001, OHSAS18001, ISO2548, GB/T3216, GB/T5657, GB19762-2005 |

| Main Application | Power plants, water supply, municipal, construction, fire fighting, industrial and mining enterprises and other industries for the transportation of water, of similar physical and chemical properties of water and other media |

Export experience:

Over 20 years’ export experience.

Company Information

ZheJiang East Pump (Group) Co., Ltd is a well-known pump manufacture in China, including scientific

investigation, manufacture, marketing and service.It owns 16 sub-businesses, 8 large manufacturing bases all over china.The sales revenue in 2014 reaches 400 Million dollars.Our products range

covers Centrifugal Pump,Stainless steel Multi-stage Pump, Submersible Pump,

Hearth-fighting pump,Magnetic Pump,Diaphragm Pump,Slurry Pump,and so forth.

BROTHER digit-control machine tools, borer, broacher, vertical lathe and large special test center run through the production flow line. Without excellent production equipment, there would not be excellent products.

The spirit of hard work is particularly presented in the production process here in Eastpump, even if a small screw, everything and every detail is made meticulously and shows the professional quality.

Eastpump strictly follows ISO 9001 quality control system, ISO 4001, OHSAS 18000etc. management systems and the scientific and reasonable flow of operation, making sure of a high effective high quality production process.

PRODUCT TESTING

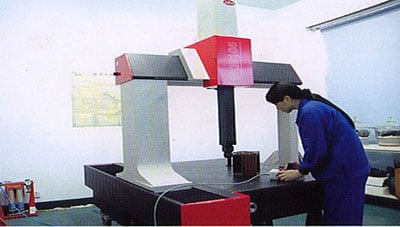

The group company now holds a large pump test center, a three-coordinate measurer, a dynamic-static measurer, a quick laser shaping instrument, a multi-functional shot-blasting machine, an automatic argon-arc welder, a large lathe, a large mill, numeral control machine tools etc. more than 2000 sets of various nationwide and worldwide advanced production and detection facilities and over 4500 staff members, of which 72.6% are graduated from colleges and technical schools, 375 hold a junior title, 28 senior, 2 national experts and 5 professors. Every year this group puts a number of capital for technical innovation, product development and equipment import and, up till now, holds up to 600 national patent technologies and takes part in the draft-out and edition of both national and industrial standards, in total of tens of the product and technical standards covering water conservancy, chemical industry, fire-fighting, city water supply etc. Fields.

Ordering instructions

Must provide order information:

The required pump model or user operating point flow, head, NPSH, the nature of the medium and temperature parameters and special parameters of the basic requirement

The pump main parts material (not to specify the configuration according to the sample delivery)

Inlet pressure (if inlet pressure >=.6MPa, pump casing should equip with high strength material)

The shaft seal type (three are mechanical seal, injectable soft-fillings seal, special seal part, packing seal and so on, it will delivery packing seal if it does not indicate)

The bearing structure type (select according to medium temperature and so on, it will deliver standard fitting if it does not indicate)

Revolving direction of pump (view from the end of transmission, the revolving direction of pump is anticlockwise. It will deliver standard fitting if it does not indicate)

Motor rotational speed, power, voltage, protection rank, insulation grade, cooling method, whether to guard against explosions and so on

Foundation: the sample 315 with the following common base frame sizes, frame sizes above 315 with a split base or no base, please specify when ordering

For spare parts, please indicate the name and quantity of spare parts required

Ordering, no special requirements to flanges book list data delivery, if any special requests when ordering

State seal flushing method: wash the external and external washing. Add the rinse water temperature is suitable for =80°C or media containing sand and other particles of the occasion

Flat flange of the pump, with the sealing surface for sealing wire required the contract specified.

Selecting description:

The order of user isn’t limited by the data which listed in the sample performance curve and performance parameter chart, this company may design and provide the products specially according to user’s actual requirement flow and head

If it is close to the listed performance parameter, it will prefer to select the standard impeller pump and the high speed pump generally (the premise is that satisfies the requirement of cavitation performance)

If user’s required flow and head parameter aren’t in the scope of product’s large flow and low head operating condition, the matched motor power may confirm and reduce properly according to the actual operating condition point.

if you have special selecting or have the unclear place to the sample, please inquire the technical support department of ZheJiang East Pump (Group) Co., Ltd directly.

Recommended spare parts: shaft, mechanical seal, seal ring, packing, bearings, impeller.

After service

East Pump persist in “consumers’ satisfaction” as our objective. “To offer consumers with high-class services” as our promises. They are embodied in our all processes of sales.

Prior to-sales service: Our engineers offer consumers design and consultation services. They will commend the optimum products, therefore, losses because of unsuitable select of pump can be averted.

Sales service: We follow the products sold on our own initiative. Consumers can receive our professional training free to ensure our products can operate with high efficiency to avoid equipment hitch owing to consumers’ incorrect use.

Right after-sales service: Our service people will forwardly make selective-check for product sold termly. Furthermore, they will supervise consumers maintaining the equipment in time. Once our products work wrong, we will obviate the trouble as soon as possible, to make equipment operate normally.

Item of service

Technical training Equipment evaluation

Installation and debugging Troubleshoot

Maintenance Update and improvement

Commitment to the service

1. After signing the contract , send engineer for assisting installation and debugging.

two. One-year warranty. Provide technical support free all-life of the products.

three. Keep all-life contacting with clients, get feedback on use of the equipment and make the products quality continually perfected.

4. Hot-line of service is available in 24h, responded in 8h. 400 1666 099

|

US $1,100 / Set | |

1 Set (Min. Order) |

###

| Impeller Number: | Single-Stage Pump |

|---|---|

| Working Pressure: | High Pressure Pump |

| Influent Type of Impeller: | Single Suction Pump |

| Position of Pump Shaft: | Horizontal Pump |

| Pump Casing Combined: | Horizontal Split Pumps |

| Mounting Height: | Since Irrigation Centrifugal Pumps |

###

| Customization: |

Available

|

|---|

###

| Water ring vacuum pump | |

| Model | 2BE1 |

| DN(flange) | 80~800mm |

| Capacity | 150~27000m³/h, with 2950RPM, 1450RPM, 980RPM, 740RPM, 585RPM, 490RPM, 372RPM, 298RPM |

| Head | 5~180m |

| Permitting working pressure | 2.5Mpa |

| Medium Temperature | Normal<=80°C, cooling structure<105°C, equal to or higher than 105°C take special orders |

| Material | Cast iron-HT200, HT250; SS304, SS316, SS316L, Duplex SS |

| Partical | 80mg/l |

| Motor | 380V, 415V, 660V; IP54, IP55; 50Hz, 60Hz |

| Shaft | Cast steel, 2Cr13 |

| Casing and cover | Cast iron, Nudular cast iron, Cast steel |

| Impeller | Cast iron, Bronze, stainless steel |

| Mouth seal | Cast iron, nudular cast iron, bronze, stianless steel. |

| Shaft seal | Mechanical seal or packing seal |

| Bearing | Closed grease lubricated roller bearing(SKF, NTN) NSK thrust and roll bearing |

| Flange standard | ASME, DIN, GB |

| Seal by | Burgmann mechanical seal or gland packing |

| Quality control system | ISO9001:2000, ISO14001, OHSAS18001, ISO2548, GB/T3216, GB/T5657, GB19762-2005 |

| Main Application | Power plants, water supply, municipal, construction, fire fighting, industrial and mining enterprises and other industries for the transportation of water, of similar physical and chemical properties of water and other media |

|

US $1,100 / Set | |

1 Set (Min. Order) |

###

| Impeller Number: | Single-Stage Pump |

|---|---|

| Working Pressure: | High Pressure Pump |

| Influent Type of Impeller: | Single Suction Pump |

| Position of Pump Shaft: | Horizontal Pump |

| Pump Casing Combined: | Horizontal Split Pumps |

| Mounting Height: | Since Irrigation Centrifugal Pumps |

###

| Customization: |

Available

|

|---|

###

| Water ring vacuum pump | |

| Model | 2BE1 |

| DN(flange) | 80~800mm |

| Capacity | 150~27000m³/h, with 2950RPM, 1450RPM, 980RPM, 740RPM, 585RPM, 490RPM, 372RPM, 298RPM |

| Head | 5~180m |

| Permitting working pressure | 2.5Mpa |

| Medium Temperature | Normal<=80°C, cooling structure<105°C, equal to or higher than 105°C take special orders |

| Material | Cast iron-HT200, HT250; SS304, SS316, SS316L, Duplex SS |

| Partical | 80mg/l |

| Motor | 380V, 415V, 660V; IP54, IP55; 50Hz, 60Hz |

| Shaft | Cast steel, 2Cr13 |

| Casing and cover | Cast iron, Nudular cast iron, Cast steel |

| Impeller | Cast iron, Bronze, stainless steel |

| Mouth seal | Cast iron, nudular cast iron, bronze, stianless steel. |

| Shaft seal | Mechanical seal or packing seal |

| Bearing | Closed grease lubricated roller bearing(SKF, NTN) NSK thrust and roll bearing |

| Flange standard | ASME, DIN, GB |

| Seal by | Burgmann mechanical seal or gland packing |

| Quality control system | ISO9001:2000, ISO14001, OHSAS18001, ISO2548, GB/T3216, GB/T5657, GB19762-2005 |

| Main Application | Power plants, water supply, municipal, construction, fire fighting, industrial and mining enterprises and other industries for the transportation of water, of similar physical and chemical properties of water and other media |

How to use the pulley system

Using a pulley system is a great way to move things around your home, but how do you use a pulley system? Let’s look at the basic equations that describe a pulley system, the types of pulleys, and some safety considerations when using pulleys. Here are some examples. Don’t worry, you’ll find all the information you need in one place!

Basic equations of pulley systems

The pulley system consists of pulleys and chords. When the weight of the load is pulled through the rope, it slides through the groove and ends up on the other side. When the weight moves, the applied force must travel nx distance. The distance is in meters. If there are four pulleys, the distance the rope will travel will be 2×24. If there are n pulleys, the distance traveled by the weight will be 2n – 1.

The mechanical advantage of the pulley system increases with distance. The greater the distance over which the force is applied, the greater the leverage of the system. For example, if a set of pulleys is used to lift the load, one should be attached to the load and the other to the stand. The load itself does not move. Therefore, the distance between the blocks must be shortened, and the length of the line circulating between the pulleys must be shortened.

Another way to think about the acceleration of a pulley system is to think of ropes and ropes as massless and frictionless. Assuming the rope and pulley are massless, they should have the same magnitude and direction of motion. However, in this case the quality of the string is a variable that is not overdone. Therefore, the tension vector on the block is labeled with the same variable name as the pulley.

The calculation of the pulley system is relatively simple. Five mechanical advantages of the pulley system can be found. This is because the number of ropes supporting the load is equal to the force exerted on the ropes. When the ropes all move in the same direction, they have two mechanical advantages. Alternatively, you can use a combination of movable and fixed pulleys to reduce the force.

When calculating forces in a pulley system, you can use Newton’s laws of motion. Newton’s second law deals with acceleration and force. The fourth law tells us that tension and gravity are in equilibrium. This is useful if you need to lift heavy objects. The laws of motion help with calculations and can help you better understand pulley systems.

Types of pulleys

Different types of pulleys are commonly used for various purposes, including lifting. Some pulleys are flexible, which means they can move freely around a central axis and can change the direction of force. Some are fixed, such as hinges, and are usually used for heavier loads. Others are movable, such as coiled ropes. Whatever the purpose, pulleys are very useful in raising and lowering objects.

Pulleys are common in many different applications, from elevators and cargo lift systems to lights and curtains. They are also used in sewing machine motors and sliding doors. Garage and patio doors are often equipped with pulleys. Rock climbers use a pulley system to climb rocks safely. These pulley systems have different types of pinions that allow them to balance weight and force direction.

The most common type of pulley is the pulley pulley system. The pulley system utilizes mechanical advantages to lift weight. Archimedes is thought to have discovered the pulley around 250 BC. in ancient Sicily. Mesopotamians also used pulleys, they used ropes to lift water and windmills. Pulley systems can even be found at Stonehenge.

Another type of pulley is called a compound pulley. It consists of a set of parallel pulleys that increase the force required to move large objects. This type is most commonly used in rock climbing and sailing, while composite pulleys can also be found in theater curtains. If you’re wondering the difference between these two types of pulleys, here’s a quick overview:

Mechanical Advantages of Pulley Systems

Pulley systems offer significant mechanical advantages. The ability of the system to reduce the effort required to lift weights increases with the number of rope loops. This advantage is proportional to the number of loops in the system. If the rope had only one loop, then a single weight would require the same amount of force to pull. But by adding extra cycles, the force required will be reduced.

The pulley system has the advantage of changing the direction of the force. This makes it easier to move heavy objects. They come in both fixed and mobile. Pulleys are used in many engineering applications because they can be combined with other mechanisms. If you want to know what a pulley can do, read on! Here are some examples. Therefore, you will understand how they are used in engineering.

Single-acting pulleys do not change direction, but compound pulleys do. Their mechanical advantage is six. The compound pulley system consists of a movable pulley and a fixed pulley. The mechanical advantage of the pulley system increases as the number of movable wheels decreases. So if you have two wheels, you need twice as much force to lift the same weight because you need a movable pulley.

The mechanical advantage of a pulley system can be maximized by adding more pulleys or rope lengths. For example, if you have a single pulley system, the mechanical advantage is one of the smallest. By using two or three pulleys, up to five times the mechanical advantage can be achieved. You can also gain up to ten times the mechanical advantage by using multiple pulley systems.

The use of a single movable pulley system also adds to the mechanical advantage of the pulley system. In this case, you don’t have to change the direction of the force to lift the weight. In contrast, a movable pulley system requires you to move the rope farther to generate the same force. Using a compound pulley system allows you to lift heavy loads with ease.

Safety Issues When Using Pulley Systems

Pulleys have an incredibly unique structure, consisting of a disc with a groove in the middle and a shaft running through it. A rope or cord is attached to one end of a pulley that turns when force is applied. The other end of the rope is attached to the load. This mechanical advantage means that it is much easier to pull an object using the pulley system than to lift the same object by hand.

Although pulley systems are a common part of many manufacturing processes, some employers do not train their workers to use them properly or install protection to prevent injury. It is important to wear proper PPE and follow standard laboratory safety practices during pulley system activities. Make sure any support structures are strong enough to handle the weight and weight of the rope or rope. If you do fall, be sure to contact your employer immediately.

editor by czh 2022-11-29